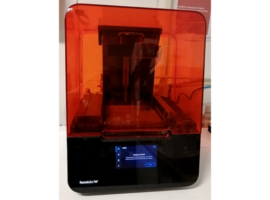

3D printers

The laboratory is equipped with two 3D printers based on SLA (Stereolithography) and FDM (fused deposition modeling).

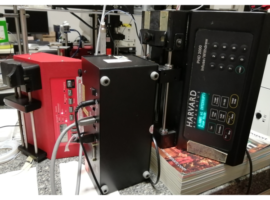

Flow and pressure control systems

The laboratory is equipped with various type of syringe pumps and pressure controllers to achieve the precise control of small amount of liquids in microfluidic channels.

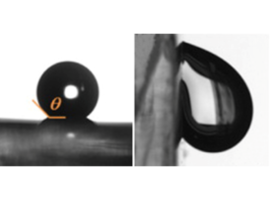

Contact angle apparatus

Custom-made contact angle setup allows measuring contact, advancing and receding angles of sessile drops deposited onto substrates (top or lateral views) to characterize wettability of homogeneous or asymmetrically patterned surface.

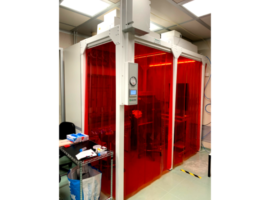

Clean room

ISO-5 Soft Wall Clean Room facility located inside an ISO-8 environment mainly devoted to microfabrication protocols based on photolithography and soft-lithography, performed in controlled conditions.

Permanent and variable magnetic field control

A large set of magnets are available in the laboratory. They are typically used for studying and manipulating ferrofluids.

Fluorescence Microscope (Nikon)

The microscope mounts different objectives (from 4x to 100x), two cameras and it typically used for flow observation (tracking), fluorescence image acquisition, microfluidic channel visualization and characterization.

UVO cleaner

UV radiation is employed to generate ozone (O3) atmosphere, a reactive allotrope of oxygen which easily oxidizes organic residues. Ozone treatment is employed to clean glass and metal surfaces.

Spin coater

Spin coaters are used to evenly spread a liquid across a surface by rotating the surface at high speed, exploiting centrifugal force, and create coatings precisely controlled in thickness.

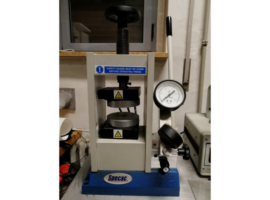

Hydraulic press

The press can provide between 0-5 tons and is equipped with a temperature controlled module. Being useful for a wide range of applications, it is mainly exploited for hot-embossing fabrication.

Oxygen plasma

Oxygen plasma can be used both in air and oxygen atmosphere, for cleaning scopes (remove impurities and contaminants from surfaces), and for bonding and sealing purposes, by surface activation.

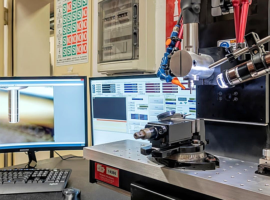

Micromilling machine

Micromilling machine is a fabricating tool that allows engraving and shaping solid substrates (mostly brass or aluminum blocks), to design channels and patterns down to hundreds of micron.

MicroMLA

MicroMLA is a lithographic machine based on high-speed direct write without using mask alignment to produce thin layers and structured patterns on surfaces (resolution of few um).